Azienda > MATEC SRL

Request info/quotes

Without obligation to the Leading Companies

MATEC SRL

Systems, equipment, services for marking, labeling, checking and coding any product, consumables

The identification and control technologies developed by MATEC allow companies of all industrial sectors to solve in a definitive and economically advantageous way all the problems of identification, coding, management, traceability, communication, control of goods being processed and finished products, services printing plates, metal labels and direct marking on any object and material.

The service offered includes, in addition to the continuous updating of the range, prompt interventions at companies.

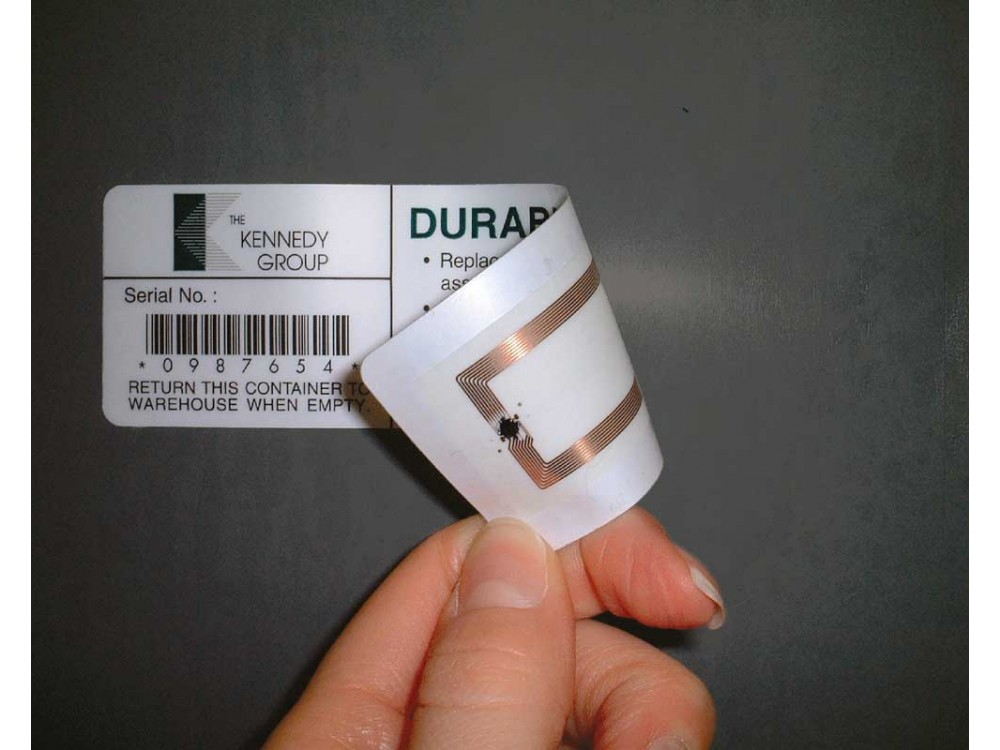

- Radio-frequency identification systems, with portal control for passing Smart Label reading on palletized packages, etc.

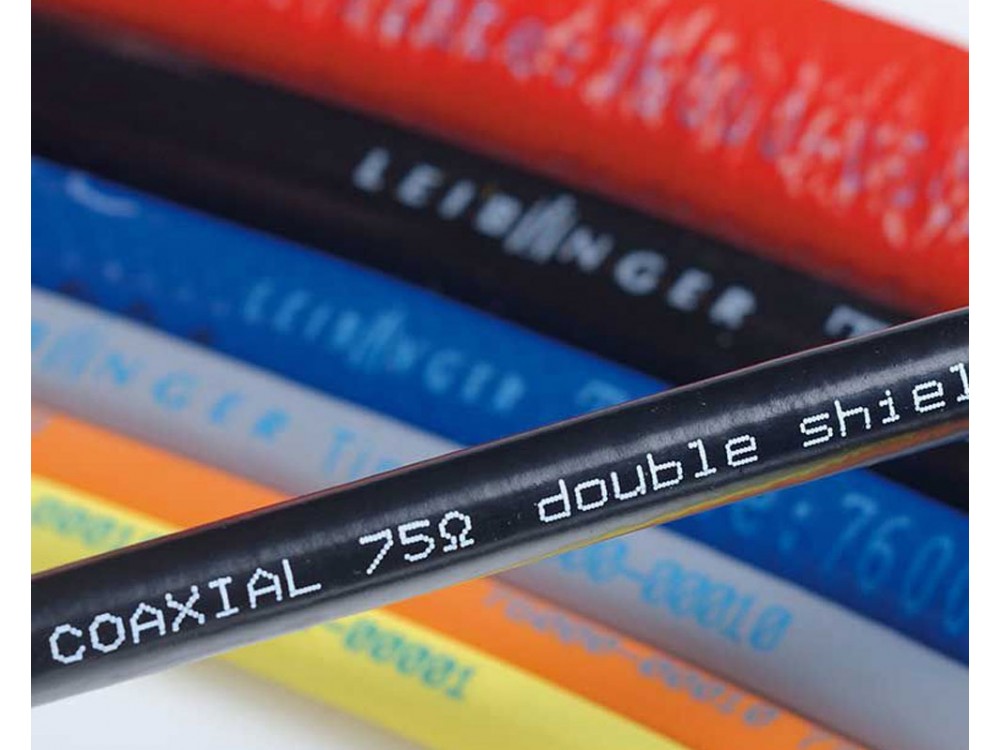

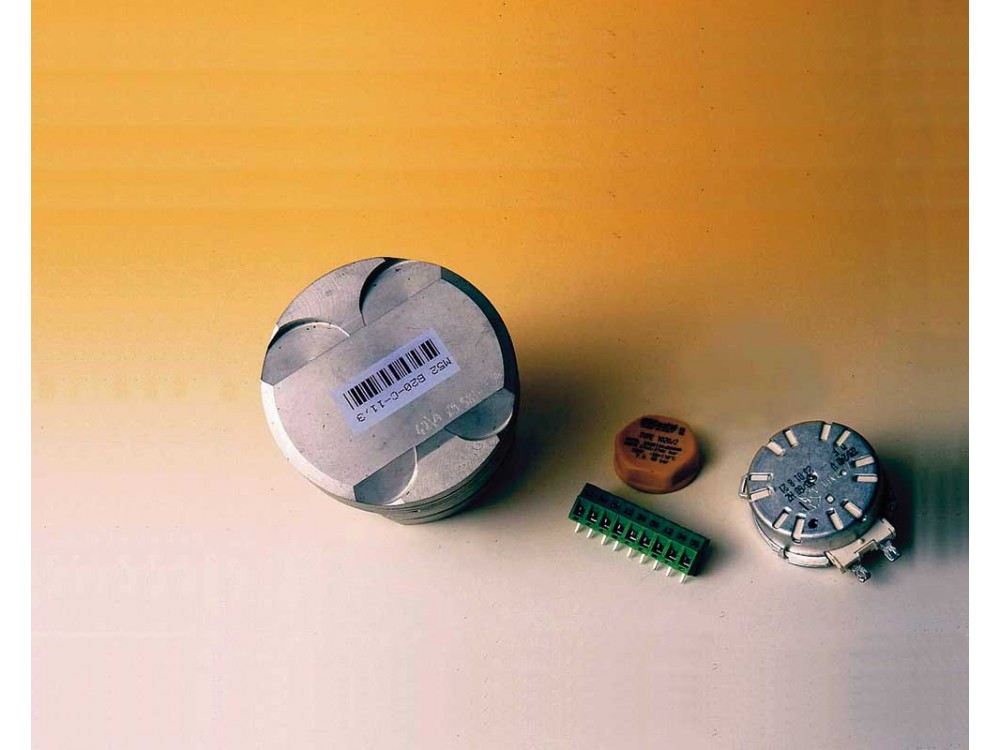

- Label applicator printers, for real-time coding and automatic label application. The data can be written in clear text or with one-dimensional or two-dimensional barcodes.

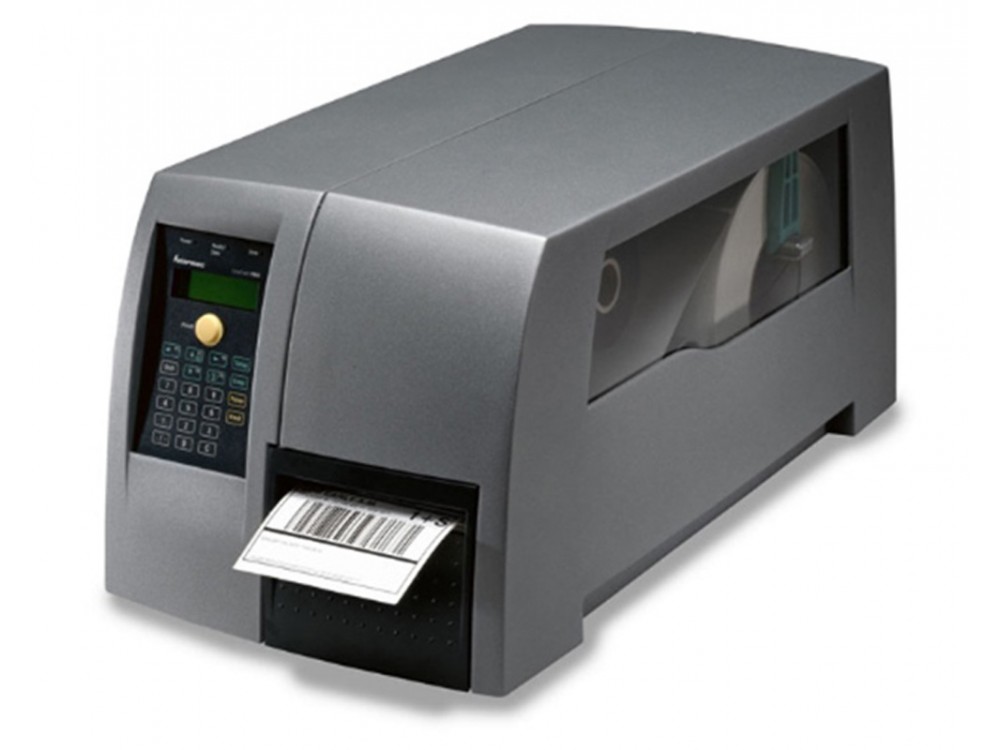

- Direct thermal transfer printers, for applications requiring the printing of one-dimensional and two-dimensional codes, product identification logos on adhesive labels, etc.

- Inkjet printers, for printing variable data, barcodes, graphics and logos on any moving object, even fast

- Dot peen markers, to code metal or plastic materials in real time. They do not use consumables

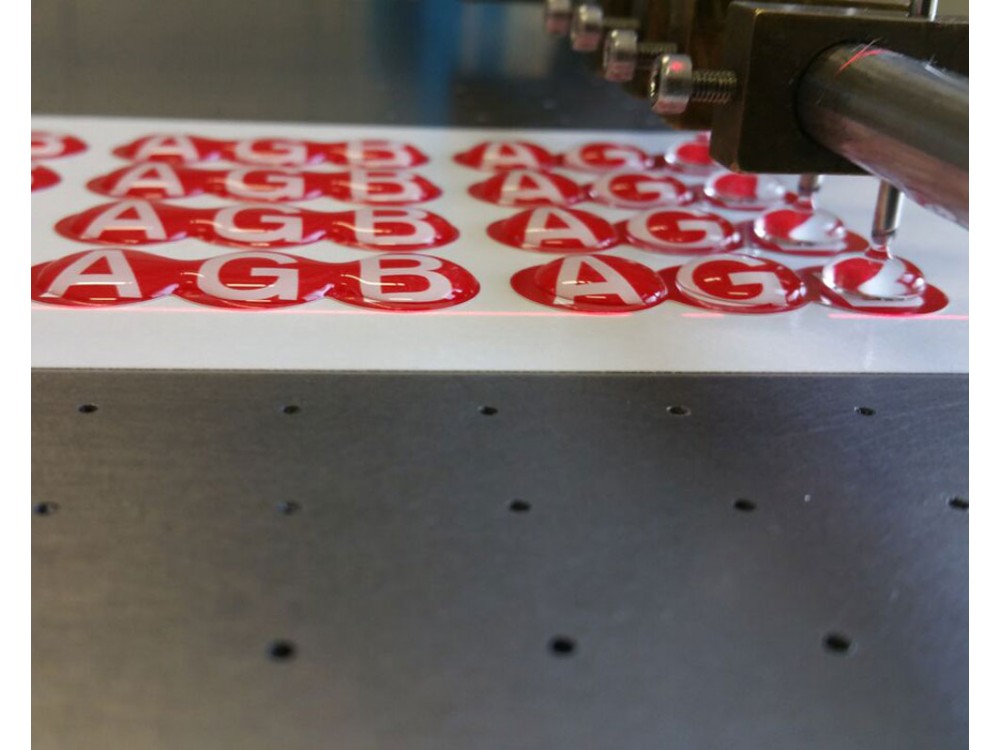

- Laser beam markers, for indelible coding of various surfaces (wood, cast iron, glass, stainless steel, plastic, ceramic, very fragile products). Also for moving products, without contact

- Stamping systems, with or without contact, to apply a sign, a symbol, a datum or for simple differentiations

- Spare and consumable materials (pre-cut, thermal, plastic, special adhesive labels, ribbons and inks, etc.

- Hot, direct impact, pad, mechanical, electrolytic, thermographic printers

The composite know-how gained by assisting numerous companies in all sectors also allows the use of more sophisticated systems and devices, which have, among their numerous functions, those of control, verification, reporting anomalies, data processing and archiving, management of downtimes. production, rationalize and order a series of operations related to processing. These systems make work safer, and are increasingly adopted as an alternative to manual or mechanical controls, which are more expensive and less reliable.

- Artificial vision systems

- Production control systems (CAP)

- Traceability management systems

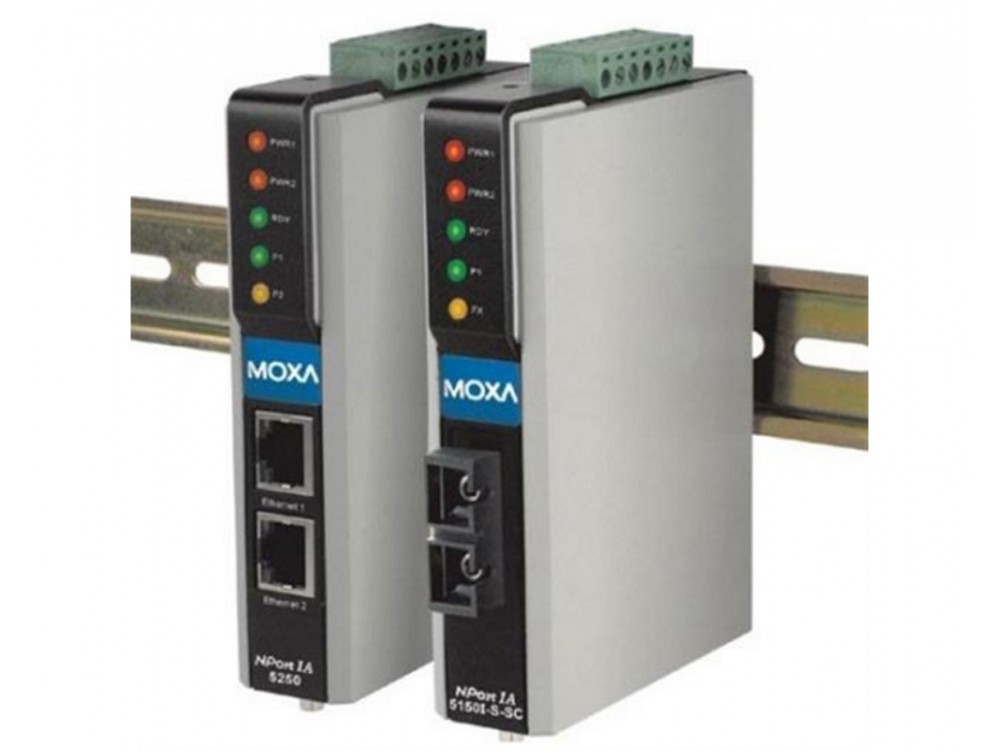

- Connectivity devices between equipment

MATEC is an ISO 9001: 2000 certified company

Read all

Contacts

- 10153 TORINO (TO) - Italy

- +39 011 23874111

- matec-122-poolindustriale.pdfDownload