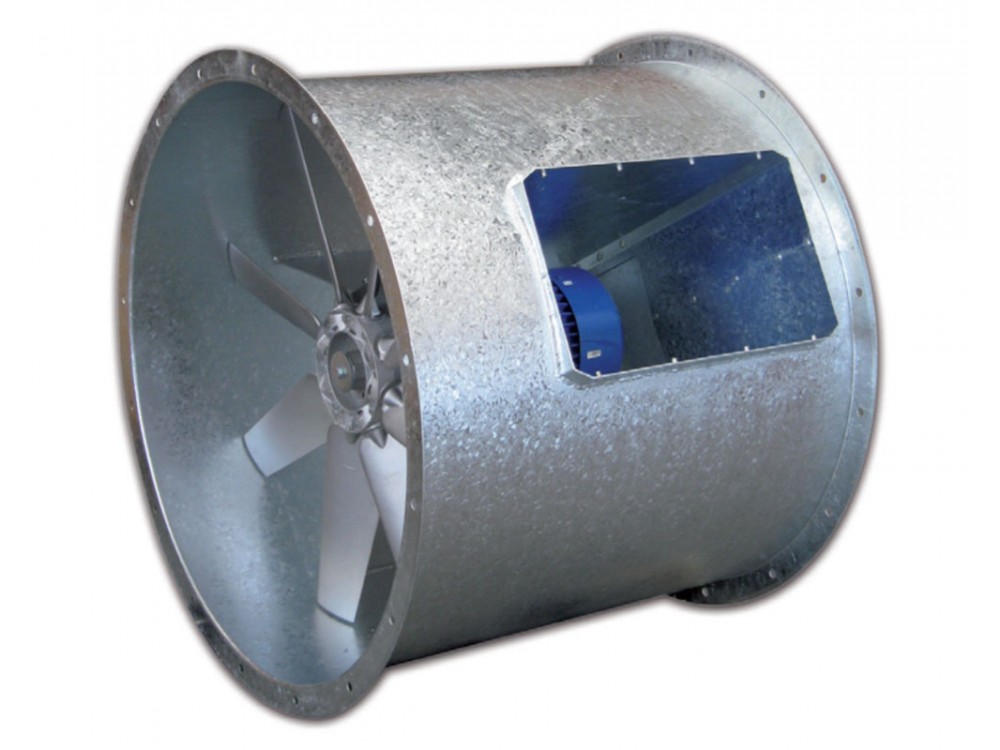

Duct-M ducted axial fan with IEC Motor

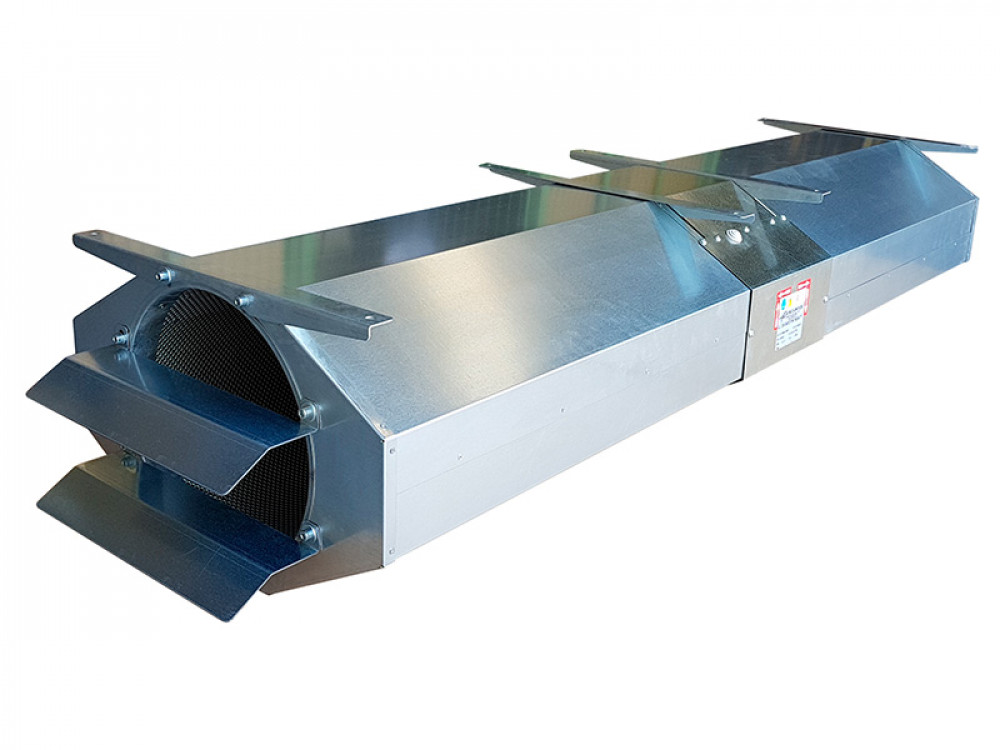

Duct- M line is suitable when large air capacities with relatively low pressures are requiredin duct mounted applications. For instance: ventilation and conditioning in naval and mining applications, evaporative towers, heat exchangers, cooling of electric and refrigerating equipments, etc. With this line is possible to attain higher pressures using the multistage version consisting of two single stages fans mounted in series, with contra-rotating impellers. This solution allows the recovery of the air rotative component turning it in pressure, developing up to 2.7 times the pressure of a single fan having the same geometry and speed.

This line consists of 15 sizes with impeller diameter from 310 up to 1600 mm.

Duct- M line is characterised by the extreme sturdiness of construction, thanks to the flanges directly bended on the casing, and the thickness of the materials. The variety of versions and models allows the solution of most of the problems of ventilation. Impeller consists of a strong hub, in die-cast aluminum alloy for the fixing of the blades. Available in different materials suitable for heavy duties.

- Casing in steel sheet protected with epoxy painting; fixing flanges according to UNI EN ISO 13351/Tab.1 standards

- Impeller with high efficiency airfoil blades in plastic material or in die-cast aluminum alloy. Hub in die-cast aluminum alloy; balancing according to UNI ISO 21940-11; variable pitch angle in still position

- Asynchronous electric motor, protection IP 55, class F insulated, form B3, service S1 construction according to the IEC/EEC (UNEL-MEC) standard

- Arrangement 4 (impeller directly coupled to motor shaft).

Versions:

- Duct-Mm: medium lenght casing: motor/impeller assembly almost completely enclosed within the lenght of the casing

- Duct-Ml: long casing; impeller and motor are completely enclosed within the overall length of the casing

- Duct-Ms: short casing; motor partially protrudes beyond the rear mounting flange

Accessoeirs: Inlet nozzle (IN) - Silencers (SIL-DU) - Flat protection grid (FPG-DU) and conic (CPG-DU) Necessary for use in free air - Inspection door - Flexible connection (FC-DU) - Antivibration mounts (AV) - Counter flange (CF-DU) - Outer terminal box (OTB) - Fixing feet (FF-DU) - Service switch (SW).

On request: Performances differing from standard - Versions with impeller with in die-cast aluminum blades - Versions with true reversible airflow (Duct-REV) - Explosion proof versions (Duct Atex) - Multistage system versions (Duct-CT) - Smoke exhaust version (Duct HT) - Versions with casing in stainless steel, aluminum, or hot dip galvanised steel - Versions with air flow from impeller to motor, position B (FGM).

Read all

Features

- Conveyed air: clean-not abrasive

- Temperature of conveyed air: -20°C/+50°C

- Voltage: three phase version (T) 400V-3Ph / Single phase version (M) 230V-1Ph

- Frequency: 50Hz

- Air flow from motor to impeller

- position A (FMG)

- DUCT-M-2019-+-ACCESSORI.pdfDownload