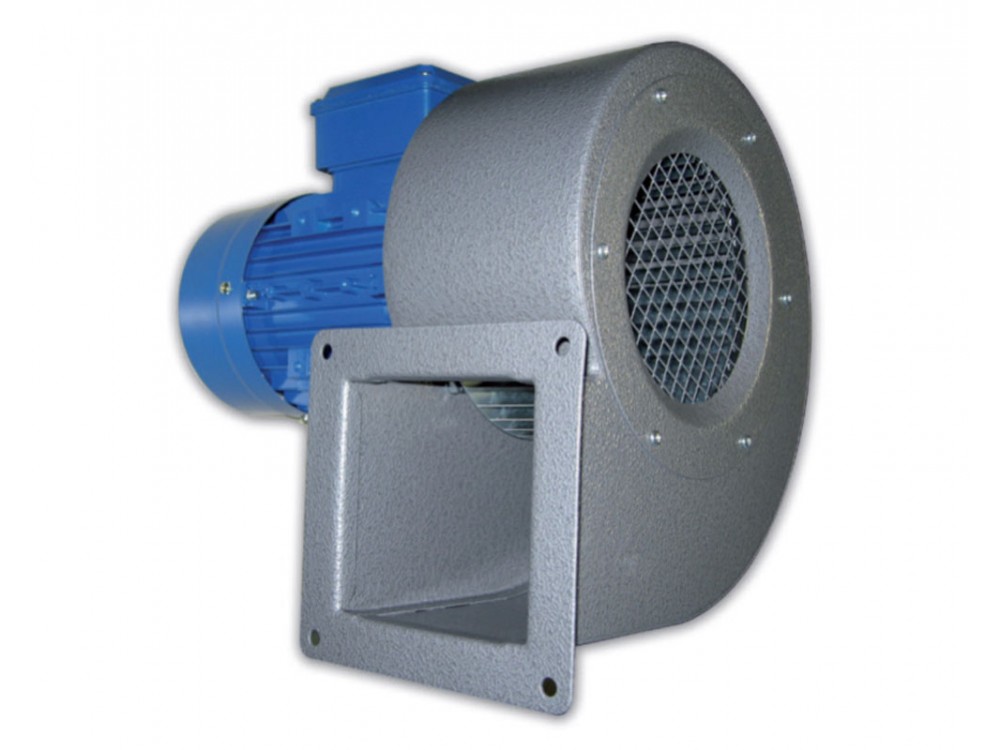

Plastic backward curved blade centrifugal for corrosive smoke

These single inlet centrifugal fans with backward curved blade impeller, thanks to their construction completely made in plastic material are used in chemical or galvanic industries or whenever there is necessity to exhaust corrosive smoke and vapours (acid, salt, etc).

This line consists of 10 sizes with impeller diameter from 200 to 630 mm.

The main features of Plastic line are the very low electrical consumption and the reduced noise level, due to the high efficiency of the backward curved blade impellers.

Another advantage is the possibility to adjust the discharge position in steps of 45° each (without any contact with the fan support).

- Backward curved blade impeller in moulded polypropylene (PP)

- Casing in moulded polyethilene (PE)

- Fan support in epoxy painted steel sheet

- Screws in stainless steel

- Asynchronous electric motor, protection IP55, insulation class F, service S1, mounting type B5, construction in conformity to IEC/EEC (UNEL-MEC)

- Arrangement 5 (impeller directly coupled to motor shaft)

Accessories: Inlet and out let flexible connections: FC-PL - Gravity shutter: GS-PL - Manual setting shutter: MAN-PL - Protection guards: PG-PL(Necessary for use in free air).

On request: Versions with casing in antistatic and self extinguishing polyethilene AST - Versions with casing in polypropylene: PP - Versions with fan support in stainless steel: Plastic-S Inox - Explosion proof Atex 3G versions

Read all

- PLASTIC-2019.pdfDownload