Ring Atex axial fan in explosive atmosphere

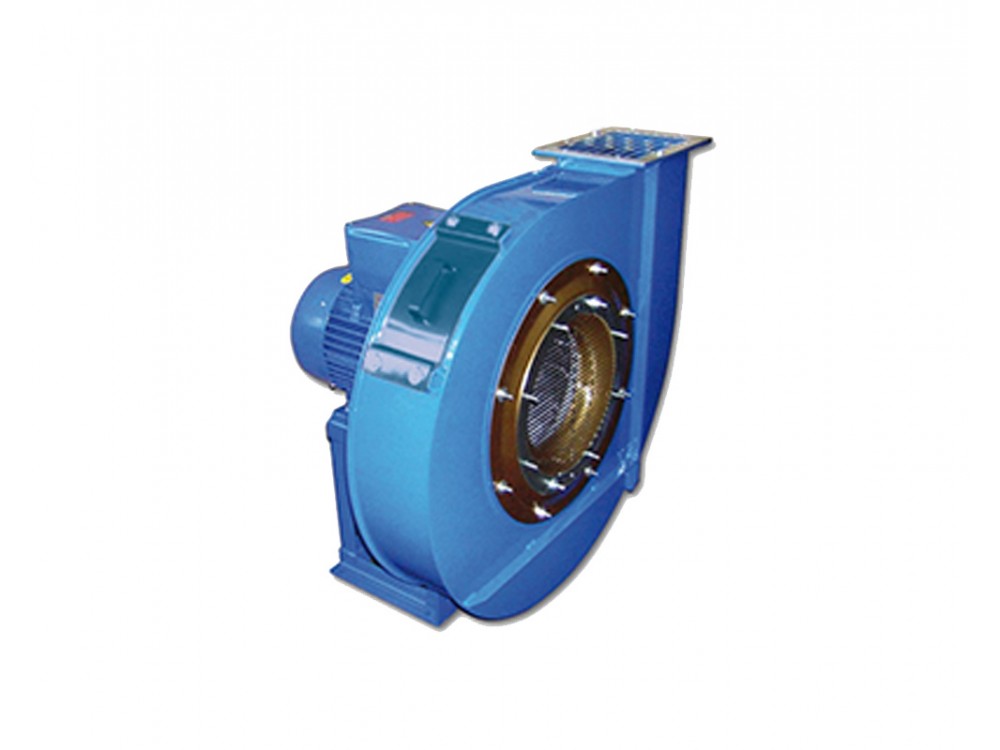

Ring Atex line is designed to grant a correct air extraction avoiding risks of explosion due to the presence of flammable gases. For instance in ventilation of battery rooms, petro-chemical platforms, laboratories etc., for wall or panel fixing.

This line consists of 13 sizes with impeller diameter from 300 up to 1250 mm.

Ring Atex line is characterized by particular materials and design to avoid as much as possible the risk of explosion, according to the Atex 2014/34/UE directive. Different constructions are foreseen for fans in category 2G, 2D or 3G, 3D.

- Ring casing , in epoxy painted steel sheet with or without aluminum stripe around the impeller rotation area

- Motor side protection grid, manufactured according to UNI EN ISO 12499 standards, in steel rod, protected against the atmospheric agents

- Impeller with high efficiency airfoil blades, in aluminum, or in antistatic plastic material, hub in die-cast aluminum alloy. Balancing according to UNI ISO 21940-11

- Variable pitch angle in still position

- Asynchronous three phase or single phase electric motor, IP55, class F, service S1, mounting type B3, according to IEC/EEC (UNEL-MEC) Explosion proof Atex approved for explosive atmosphere G or D group II

- Arrangement 4 (impeller directly coupled to motor shaft)

Versions: Ring DR - casing with double round shaped nozzle; Ring SR - casing with single round shaped nozzle.

Accessories: Protection grid, impeller side (FPG-RI) (Necessary for use in free air) - Gravity shutter (GS) (for safe area) - Square panel (SQ) - Fixing feet (FF-RI).

On request: Performances different from catalogue - Versions with 100% reversible air flow (RING-REV) - Versions with conveyors in stainless steel, or aluminum or other materials according to the actual directives - Versions with casing with one round shaped inlet and flat flange impeller side (Ring DRP-G) - Versions with casing with one round shaped inlet and flat flange motor side (Ring DRP-M) - Versions with air flow from impeller to motor, position B (FGM).

Read all

Features

- Conveyed fluid: clean gas-not abrasive or corrosive

- Temperature of conveyed fluid: -20 °C/+40°C

- Voltage: three-phase version (T) 400V-3Ph - 50Hz / Single-phase version (M) 230V-1Ph 50Hz

- Air flow from motor to impeller - position A (FMG)

- RING-ATEX-2019.pdfDownload